Here are two types of general Silicone heat transfer. We will explain in detail below:

The first type, the most commonly used slicone heat transfer, is to repeatedly print multiple layers with silicone ink , and finally reach a thickness of 0.8mm. We will also call it 3d heat transfer.

This type of process is relatively demanding, so generally small factories are not good at printing. Some even don’t have this technology. But it is the printing method that is currently popular all over the world!

Generally suitable for more sports and leisure models, patterns generally use numbers, letters, geometric patterns, lines and so on.

Special heat-drying is required for silicone heat transfer printing to ensure that the material is free of moisture. Because if a good heat transfer is produced and there is no drying process, when the customer uses the heat transfer machine to decompress, the water inside evaporates, which directly destroys the deconstruction of the glue behind. And the heat transfer cannot be transferred to the clothes, or after washing easy to fall off!

Igingle attaches great importance to product quality, and all heat transfers are washed tested before shipment.

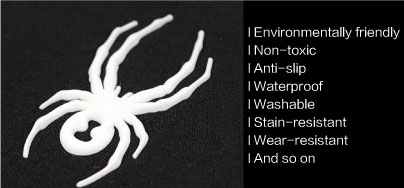

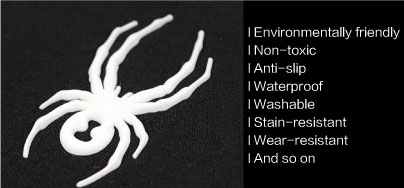

Silicone heat transfer is environmentally friendly, non-toxic, anti-slip, waterproof, washable, stain-resistant and wear-resistant, can stands high temperature and extremely low temperature, high weather resistance and not easy to aging, can keep the pattern color bright without fading.

The surface of the product is smooth and feels good. The combination of pattern and fabric can produce high firmness. Silicone heat transfer is widely used in clothing, luggage stationery, shoes, hats, non-woven fabrics and many other fields.

The stamping temperature is 135-150 degrees. The stamping time is 8 seconds on the front and 12 seconds on the back.

The above is the most commonly used silicone heat transfer on the market. But its disadvantage is that the top is flat. When many customers go to research the heat transfer, they will find that some are arc-shaped thick heat transfer. Yes, this is the second type of heat transfer.

Its production process uses mechanical equipment to process some copper molds, and then heat the silicone gel to make it become a liquid and slowly drip on the mold.

After completion, it is dried, and then a layer of glue is applied to it, and the drying is continued. After secondary drying, put the finished product on the PET film with the adhesive removed and send it to the customer.

The biggest highlight of this type of trademark is that if your pattern lines are very thick, you can achieve a thickness of up to 7mm, and the three-dimensional effect is very strong. Of course, compared to the first type of silicone heat transfer, the price is much higher. The hot stamping temperature is 150-170 ℃, and the hot stamping time is 15 seconds on the back.

I hope our explanation is helpful to you. Thank you!

⁄ USD

⁄ USD