We have been produced heat transfer printing for 8 years and received lots of complaints from our clients that they cannot make the heat transfer printing successfully.

Every time we face this kind of complaint, the first thing we do is to comfort our clients and hope they can understand. Indeed, all of our heat transfer printing products,

we must arrange a washing test for more than 10 times by 5A washing machine, so there will be no quality problems basically.

Now we will list the common problems why cannot heat transfer printing sucessfully:

1. Equipment problem

There are some clients who are not professional clothing manufacturer, they do not have a professional heat transfer machine either.

Some clients operate with a household electric iron. It is available to heat transfer by using household iron but has to have a certain level of skill.

Some clients do not operate improperly so cause a bad effect. Also, the contact surface between the household and the fabric is unstable.

That's will cause uneven hot stamping, uneven pressure or temperature problems.

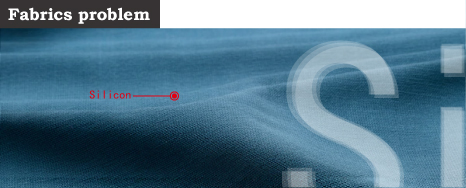

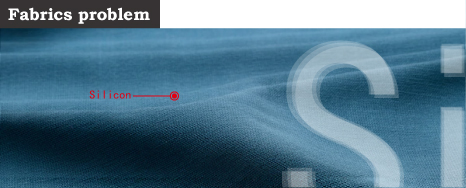

2.Fabrics problem

This kind of problem basically occurs in the wash after the heat stamping off phenomenon.

Many ready-to-wear fabrics are coated with Si(Silicon) in order to feel smooth when touching it. As the glue and silicon are insoluble, just like oil and water, they do not mix.

It causes the heat printing cannot laminate fabrics that will be easy to come off after washing several times.

In order to avoid this kind of problems, customers have to check the fabric component when purchasing garments or fabrics. Remembering not to purchase the fabric with silicon coated.

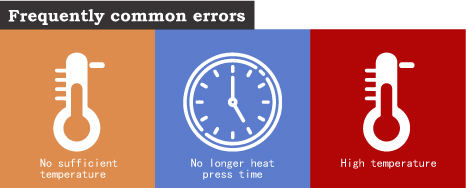

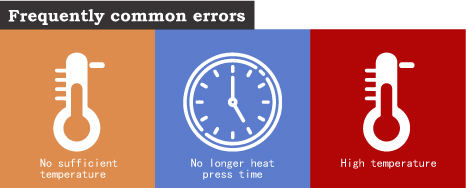

3. Frequently common errors

No sufficient temperature, No longer heat press time, High temperature. This kind of problem is relatively rare.

4.Aging of heat press machine

Maybe there are many clients say they have a professional heat pressing machine, it must be our product problem. There are the following problems after your machine older than one year.

1) the real temperature differs from the heat press machine screen. Generally, after using a heat press machine for a long time, the actual temperature will appear much lower than the display temperature of the device.

2) Not enough pressure. In the process of many years of hot stamping, the spring of the machine has been at a high temperature, resulting in insufficient elasticity. Or the underside of the machine is loose, resulting in the upper surface and underside in the process of hot pressing, the pressure can not meet the requirements of the hot stamping. Generally, the pressure should be more than 3KG.

5.Uneven coverage

Many small and medium-sized customers purchase ready-made garments and then arrange heat transfer printing by themselves.

The surface of garments is uneven, especially the place of the neckline of Polo-T-shirts. Many washing printing crafts are not successful,

for the reason of different thicknesses of the neckline, so that the stress is different, which the heat transfer fails.

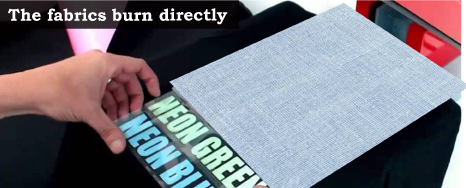

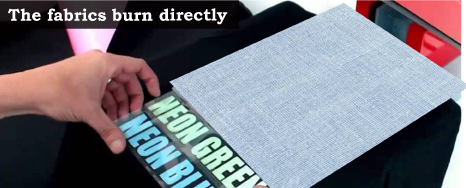

6. The fabrics burn directly

Heat printing of the temperature is above 120 degrade centigrade. Some fabrics will be wrinkle or damage when they come in contact. Actually, you don't need to worry, you can first put the garments on the heat stamping machine, then put the transfer printing, and cover a layer of cotton on the clothe finally. So that the fabric of garments cannot touch the machine directly. It is really a perfect way that not only meets the requirements of hot stamping but also can avoid damage to the fabric.

If you have any other questions, please contact us.

The following link is for purchasing heating transfer labels. Looking forward to your feedback.

https://www.igingle.com/c/heat-transfer_0361  ⁄ USD

⁄ USD