1.Tagless heat transfer

100% cotton, most 100% polyester, cotton/poly blends, mesh, canvas, Lycra, spandex, knit rayon

This kind of label mainly uses the crafts of screen printing, the logo is basically single color, but it also has several colors. Information about the heat transfer label mainly includes logo designing, washing requirements, size, original, etc. Most of the labels are sewing on the place of the neckline. Some neck labels are use woven labels for the reason of bad feeling to the skin. That's why heat transfer is very popular. This tagless heat transfer can use on many materials like 100% cotton, most 100% polyester, cotton/poly blends, mesh, canvas, Lycra, spandex, knit rayon.

The temperature of heat transfer: 130-150 degree centigrade

Time of heat transfer: 10-12 seconds

We default hot tearing, but we can also make cold tearing

2. Colorful heat transfer

This kind of heat transfer mainly refers to the colorful design. The size of the colorful design is about 10"x10", and use in front of the chest or back. Its material is plastisol that is the same as tagless heat transfer. This colorful heat transfer can use on several materials such as cotton, non-woven polypropylene, polyesters, nylons

The temperature of heat transfer: 130-150 degree centigrade

Time of heat transfer: 10-12 seconds

We default hot tearing, but we can also make cold tearing

3. Reflect heat transfer

Just as the name mentioned, this kind of heat transfer has reflection especially at night under the light, which makes the people who wear the clothes very shinning. It is a great way to show fashion. This reflects heat transfer can use on the materials like Cotton & Cotton blends, Polyester, Rayon, Nylon

The temperature of heat transfer: 150-degree centigrade

Time of heat transfer: 10-12 seconds

cold tearing

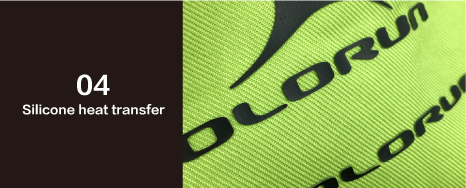

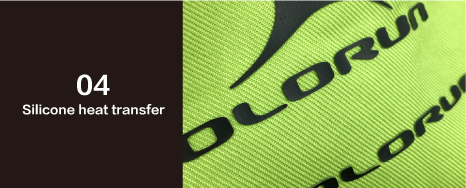

4. Silicone heat transfer

The thickness of silicone heat transfer is about 0.8mm, it is a popular way to print on the chest, the size of most logo is about 2" width, 1-3 colors of logo basically. This kind of silicone heat transfer mainly use on Cotton & Cotton blends, Polyester, Rayon, Nylon

The temperature of heat transfer: 150-degree centigrade

Time of heat transferring: press 10 seconds on front and 12 seconds on the back

Cold tearing

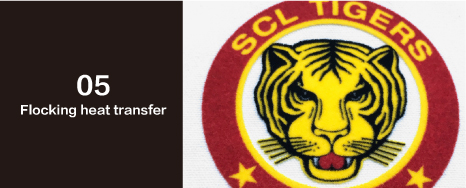

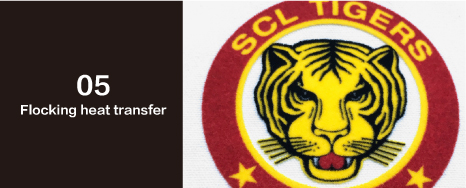

5. Flocking heat transfer

Sofft flocking surface is the first choice for children's clothing. It is divided into monochromatic flocking and multicolor flocking. Monochromatic flocking is dyed at high temperatures, so the color is very firm. On the contrary, the color fastness of multicolor flocking is not stable but basically does not affect the product quality. This kind of flocking heat transfer mainly use on Cotton & Cotton blends, Polyester, Rayon, Nylon.

The temperature of heat transfer: 150-degree centigrade

Time of heat transfer: 10-12 seconds

cold tearing

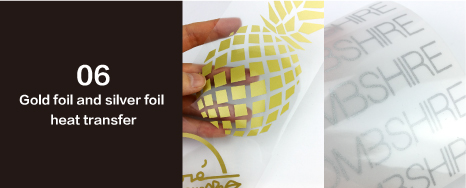

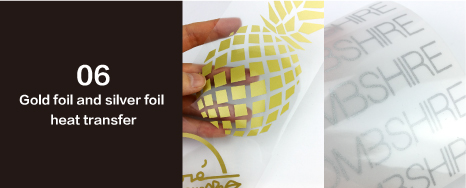

6. Gold foil and silver foil heat transfer

The workmanship of gold foil and silver foil heat transfer is a kind of screen printing, then heat transfer glue on the back of gold or silver foil. It is just to immobilize the pattern on the material by using glue. That's to say, this kind of pattern can only coloring gold or silver. It is widely used on Cotton & Cotton blends.

The temperature of heat transfer: 150-degree centigrade

Time of heat transfer: 10-12 seconds

cold tearing

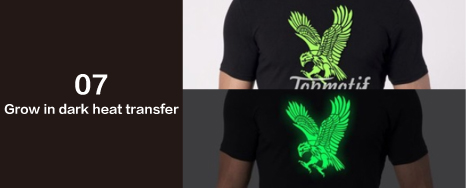

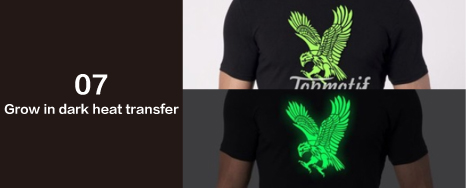

7. grow in dark heat transfer

It's a heat transfer that absorbs sunlight and releases under a dark environment. Not so many people use this kind of heat transfer, but it is very popular by young people. This kind of workmanship widely use on cotton& cotton blends

The temperature of heat transfer: 150-degree centigrade

Time of heat transfer: 10-12 seconds

Default hot tearing also can make cold tearing

8. PU heat transfer vinyl

The material is a polyurethane film. roller film cut by cutting plotter to clients' pattern, then remove the unwanted parts. There are 24 colors, 50cm x 250cm/per roll. Many clients prefer to have varieties of colors into 10" x 10" sizes which pack and retail them together. PU heat transfer vinyl is suitable for cotton, silk, hemp, wool, nylon, polyester, and other fabrics.

The temperature of heat transfer: 150-degree centigrade

Time of heat transfer: 10-12 seconds

cold tearing

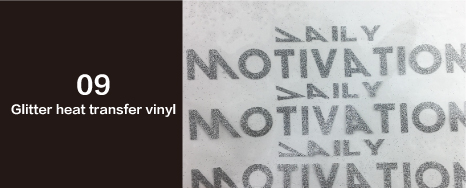

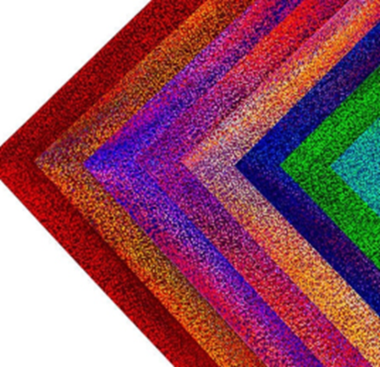

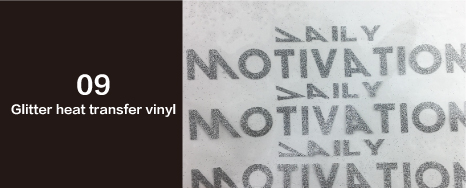

9. Glitter heat transfer vinyl

Same as PU heat transfer vinyl, it is very popular with clients, Normally uses on the material like cotton, uncoated polyester, cotton/ poly blend. It is not recommended to be used on too elastic fabrics. There are about 30 kinds of styles to choose, 50cm x 250cm/ per role. Many clients would like to cut them to different sizes like 10" x 10", 12" x 12", and then put different colors of products together for sale. Hence, it is used on medium stretch fabrics like cotton

The temperature of heat transfer: 150 - 160-degree centigrade

Time of heat transfer: 12 - 15 seconds

Tied tearing

If you have any other questions, please contact us.

If you purchase this kind of product, please click here.

⁄ USD

⁄ USD