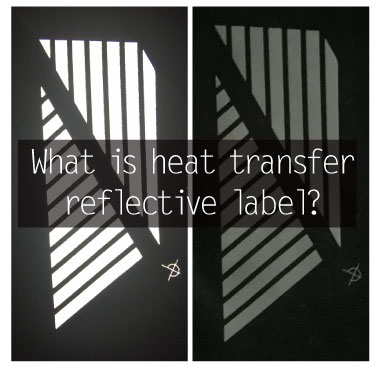

The characteristic of reflective heat transfer is to reflect the light source at night or in a dark environment to achieve a warning effect. Used for police clothing, road maintenance clothing, etc. With the popularity of reflective heat transfer, many sports enthusiasts and fashion apparel brands have started to use reflective heat transfer. When running at night, reflective heat transfer can remind surrounding vehicles to pay attention to the presence of night runners. In the fashion industry, wearing reflective clothing is particularly prominent and attracts the attention of the surroundings.

How do we use reflective heat transfer?

There are basically three types of reflective heat transfer on the market.

1. Screen printing reflective heat transfer. The reflective ink is printed on a PET film through a silk screen process and subjected to a high-temperature drying treatment. After packing, send it to the customer company.

2. Reflective lettering film. Enter the design into the computer, and the plotter will follow the computer system prompts to engrav. Remove the unnecessary parts, leave the logo design, and send it to the client company.

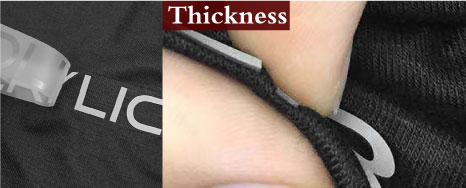

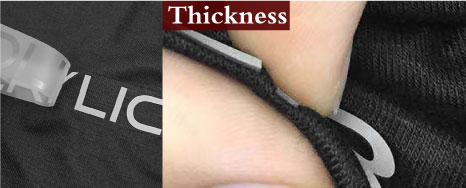

3. Thick plate reflective heat transfer. It is also made by wire mesh process, but the thickness of the product can reach 0.6mm.

What's the difference between them?

Let's first compare the two types of products 1 and 2 because they are 2D effects.

A.The trademark and glue of screen-printed reflective heat transfer will shift a little. This is a common problem of screen-printing process, so after professional clothes, the glue will overflow around the trademark a bit.

However, the glue and pattern of the reflective lettering film are integrated. When it is transferred to the clothing, it is a perfect fit without any flaws around it.

B. Comparison of reflective effects. The screen printing effect will be slightly lower than that of the lettering film. And the reflective film heat transfer of the lettering film will not change after washing.

But the screen printing reflective heat transfer will be a bit lighter.

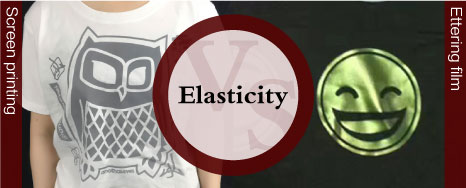

C. Lettering film reflective heat transfer will be slightly inferior to screen printing reflective heat transfer in terms of elasticity.

Therefore, the reflective heat transfer of the lettering film is more suitable for non-elastic fabrics. The screen printing reflective heat transfer is particularly widely used in sportswear.

D.The color of the reflective film of the lettering film can only be made into a single color, and the selectivity is very small.

However, the screen reflection can be multi-colored or dazzling. Although the effect is not as good as the gray reflection, it is also very popular with customers.

The difference between the third type of reflection and theirs is that it has a little thickness. When you touch the trademark by hand, you will have a certain feel. Other features are exactly the same as screen-printed reflective.

If you have any questions about our reflective heat transfer, please contact us as soon as possible. Thank you!

⁄ USD

⁄ USD