How to make heat transfer?

Written By Manager

What is a heat transfer?

Printing heat transfer is essentially a heat transfer process. A method of fixing your favorite patterns to clothes or other places where you can paste them. This technology is commonly used in clothing and automotive products, such as custom T-shirts and label applications. Because the heat transfer process ensures that the design is embedded in the sublayer of the printing surface, the design will make the garment last longer.

How many types of heat transfers are there?

The following seven types on igingle's website:

How many types of heat transfers are there?

The following seven types on igingle's website:

1.Silionce heat transfer

2.full color heat transfer

3.tagless heat transfer

4.Flock heat transfer

5.PU heat transfer

6.Glitter heat transfer

7.Reflect heat transfer

How to make heat transfer?

1.First you need to design the pattern you want. The pattern will be printed on special transfer paper or synthetic film and then printed on clothes.

2.Secondly, printing methods include screen printing, flexographic printing, digital printing, etc. Igingle has professional heat transfer machines for mass production of label-free labels and heat transfer printing.

3.Then use a heat press machine to apply the printed pattern to the clothes by hot pressing at a specified pressure and precise time at a controlled temperature. Igingle has small and large heat press equipment for you to make.

4.Place the heat transfer label on the press, and then put the printed transfer paper or film on the top so that the two touch.

5.The heat press machine is set to the recommended pressure and time.

6.Lower the handle to close the heat press machine; an alarm will sound when the time is up.

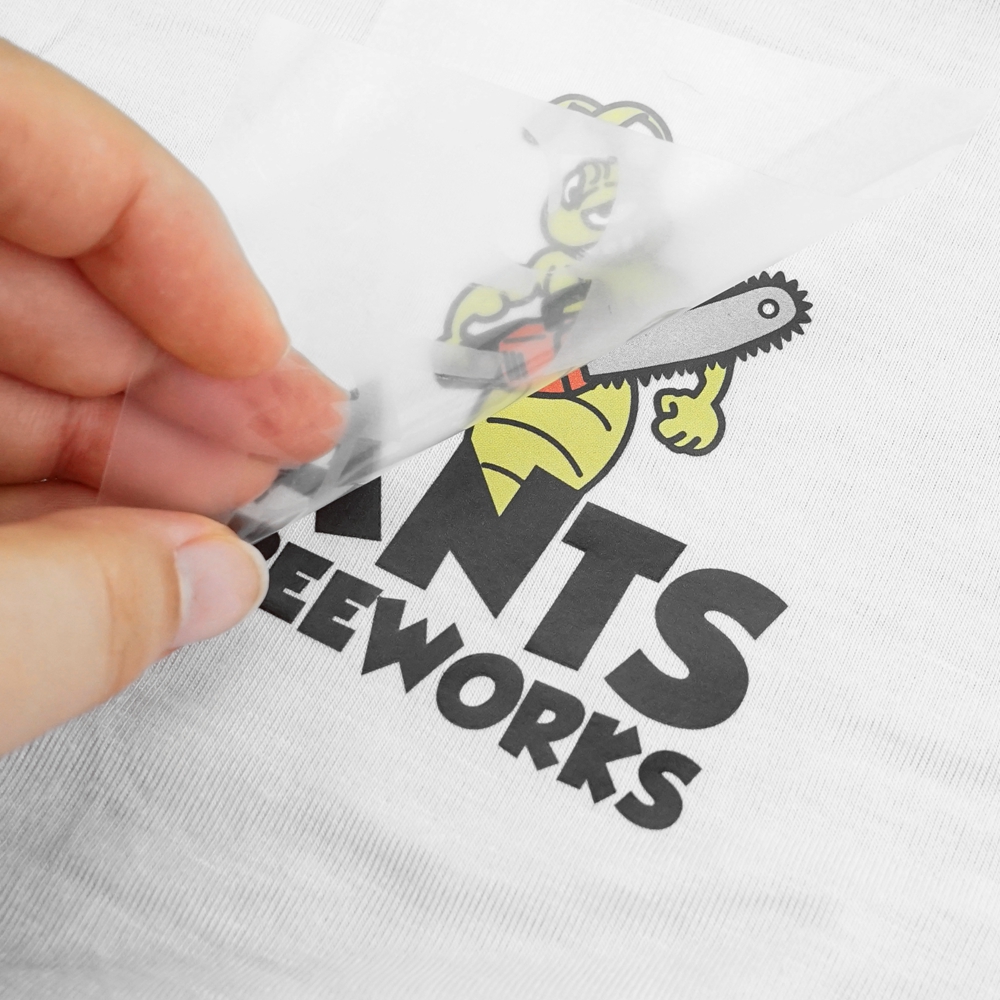

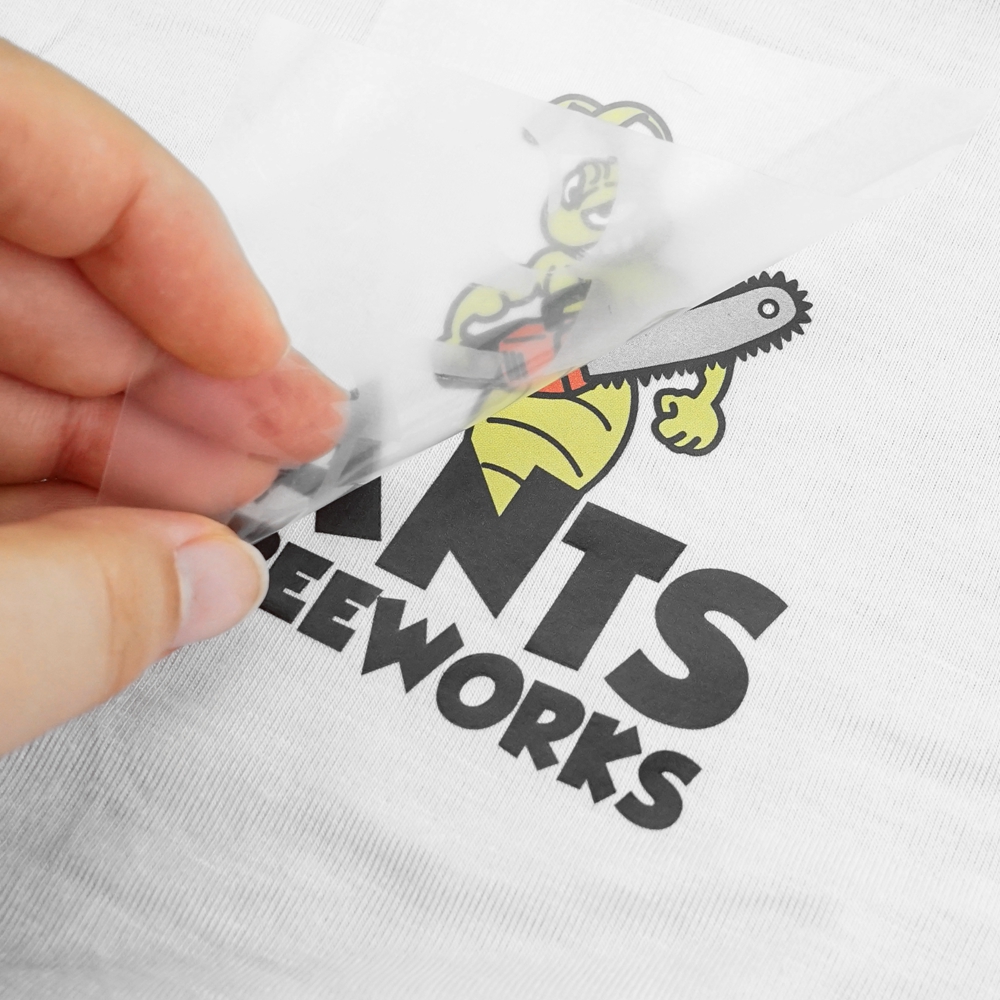

7.Finally, peel off the transfer paper (note that some products will be peeled off when they become cold; other types should be removed at a constant temperature), and the pattern will be printed on the clothes.

⁄ USD

⁄ USD