Resin buttons are a big category of buttons. It has been well received by the public. Igingle provides the service of engraving trademarks for customers. Let the small buttons show your brand. Cash out the high-end of your clothing, the pursuit of details!

Do you know what his production process looks like?

1. Raw materials:

Unsaturated polyester is a raw material extracted from petroleum and is a transparent viscous liquid. The resin with the catalyst and hardener can be added with different color pastes, or other raw materials, such as wax, salt, wood chips, straw, etc., different amounts of raw materials at different concentrations, different temperatures, different speeds and special With the cooperation of accessories, it will produce ever-changing patterns, and it is also an important material that can be made into imitation natural buttons such as pearl oysters, horns, fruits, wood grain, stones, marble, etc.

2. Board:

Pour the fully mixed resin into the rotating centrifugal bucket, and pour multiple layers as needed. After about 30 minutes, the resin in the bucket is soft and gelatinous due to the chemical reaction. It can be cut into slices and placed on the embryo punch. Push the button embryo out.

3. Stick flower:

The completely mixed glue is poured into the waxed aluminum tube through a special swinger, and the glue stick is sliced out of the aluminum tube when the glue becomes soft and gelatinous.

4. Embryo:

All stick embryos are soft and must be placed in hot water at 80 degrees for 10 hours to accelerate the chemical reaction. After the reaction, the germ particles are hard embryos.

5. Button section:

The automatic button machine can pass through the car face, the car bottom and punch holes at one time, and even the lettering and engraving can be done in one pass. Ordinary four-hole button with side and car bottom, can engraved 100 tablets per minute, the same as the embryo and stick embryo.

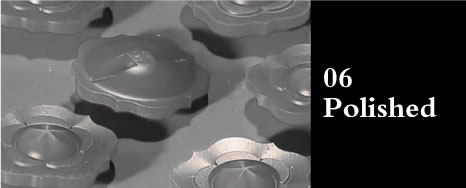

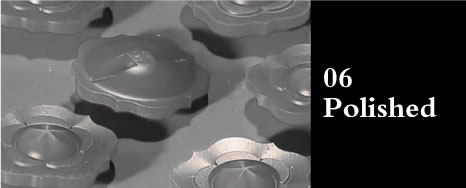

6. Polished:

Because knife marks are left on the car surface and the bottom of the car, it needs to be put into a water mill barrel to smooth it. The slowly rotating water mill barrel contains water and lime powder. This process takes ten hours. After grinding the button, the button has a matte effect. If you want to brighten the effect, you must light it up. The bamboo core and wax are mainly placed in the brightening barrel. This process takes 20 hours. To achieve the above effect, this process takes fifteen hours.

Resin buttons with custom logos are formed.

If you have further questions, please contact us. Thank you!

⁄ USD

⁄ USD